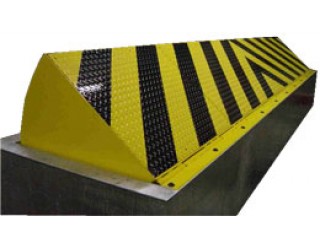

Hydraulic, surface mounted security road blocker for important places and buildings requiring higher degree of security.

The Road-Blocker is widely used to control vehicular access at high security and medium-high security sites all over the World. It is also increasingly being used to provide vehicle access control at sites which, whilst not “high security” nevertheless have problems such as car theft, vandalism, avoidance of parking charges and illegal parking / access. It is also used to provide complete protection of premises which might be otherwise vulnerable to “Ram-Raiding”. However the most familiar locations for the Road-Blocker are still Military Bases, Entrances to Bank Vaults, Cash in Transit and Security Guarding Companies, Police Stations, Airports, Power Stations, Government Buildings and Embassies.

The Road-Blocker is extremely durable and reliable as it is build to very high standards with the finest materials. Provided it is maintained in accordance with the manufacturer’s instructions, it will give many years of trouble free service.

Functions and Features

Strong and durable structure, great capacity of weight bearing;

Stable movement, low noise;

Workable in bad weather environment;

Adopting low hydraulic pressure driving measure, few failure happening, dependable and long serving life;

Simple and easy maintenance;

Compatible with other controlling facilities to achieve automatic control;

Manual operation mode can be used in power off or accidental cases; the raised gate plate can be put back to its horizontal position by manual operation.

Main hydraulic components are imported well-known products, which ensure the dependable quality and long serving life.

The barrier front face is formed by curved plating closed at both ends, white enamelled with chevron-shaped red reflecting stripes, which encloses the mechanism.

Metal frame sealed into the concrete pit.

Hydraulic power unit (not presented on the illustration), to be placed separately from the Road Blocker, containing:

- motor,

- hydraulic pump,

- oil accumulator,

- oil tank,

- filter with plug and oil gauge,

- hydraulic valves,

- manometer,

- pressure regulator and security valve,

- Push button box (open – stop – close).

Technical Parameters-k-12

High strength restrictors to protect the hydraulics from damage.

- Carrying capacity–20 tons

- Voltage: 380V or 220V (optional)

- Power consumption: max. 1.5 kW

- Rising part height: 300mm ~ 750mm (optional)

- Standard rising and lowering times: between 3 and 5 seconds.

- Hydraulic oil type:45#hydraulic oil or Anti-Freezing oil

- Working Environment Temperature:-20℃—+55℃

- Emergency manual override system for use in the event of a power failure.

- Compatible with all types of access control and safety systems.

- Fully galvanized frame and blocker unit with painted finish.

- IP65 rated control panel housing.

Options

- Additional LED traffic light.

- Post to install traffic light(s)

- Longer hydraulic hose:

Work to be provided by the customer

- Power supply to the control unit.

- Electrical connection wiring between the control unit, the hydraulic power unit, the traffic light(s)

- Reinforced concrete pit with rainwater drainage and fixing frame installation (3)

- Installation of hoses between the pit and the power